An Artifact From the Future, Custom-Made for Ballantine’s

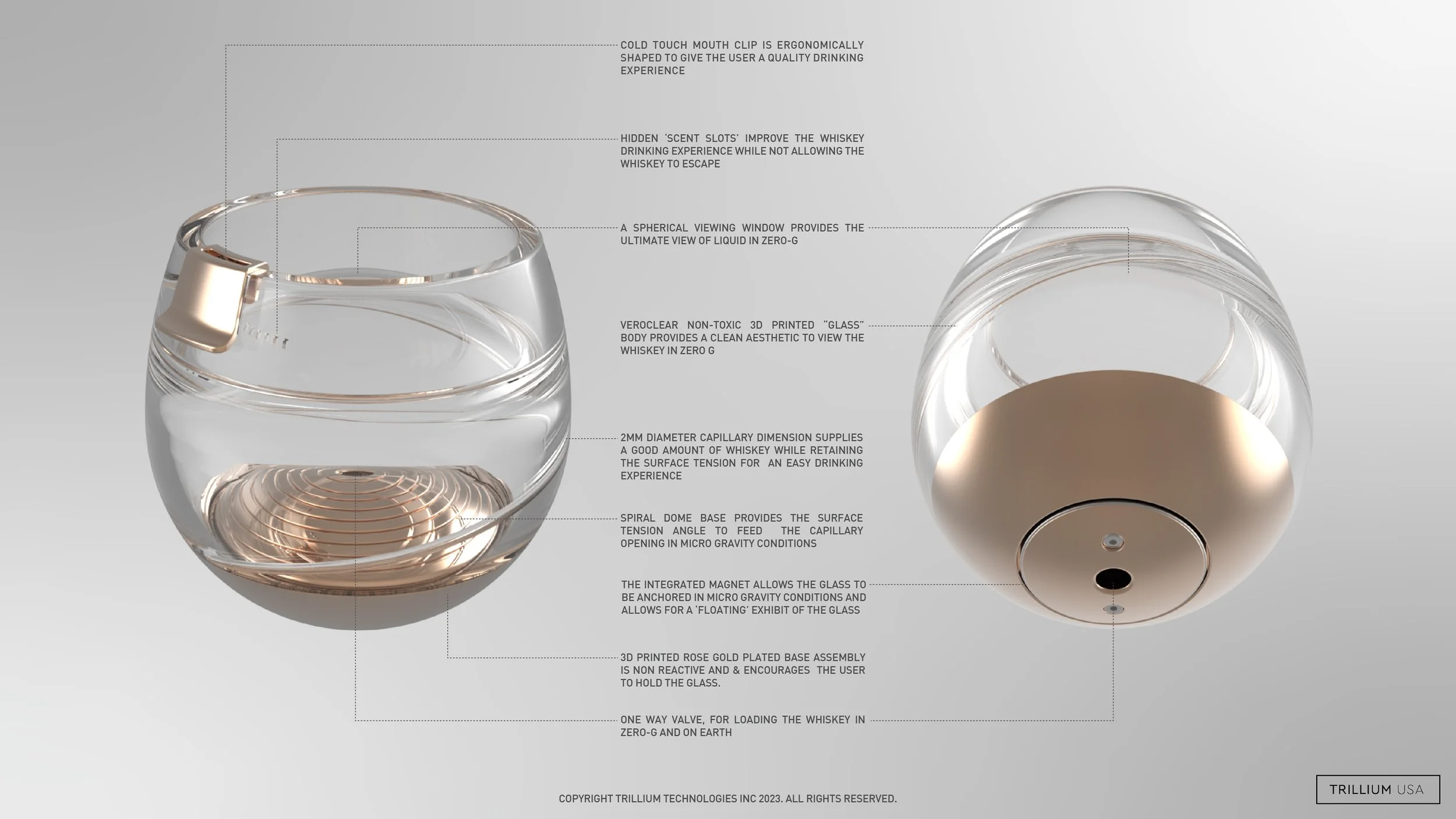

The initial idea was simple: design a whiskey glass that can be used in zero-gravity. But Ballantine’s wanted more than a practical solution, they wanted a design that captured the beauty and expansiveness of space.

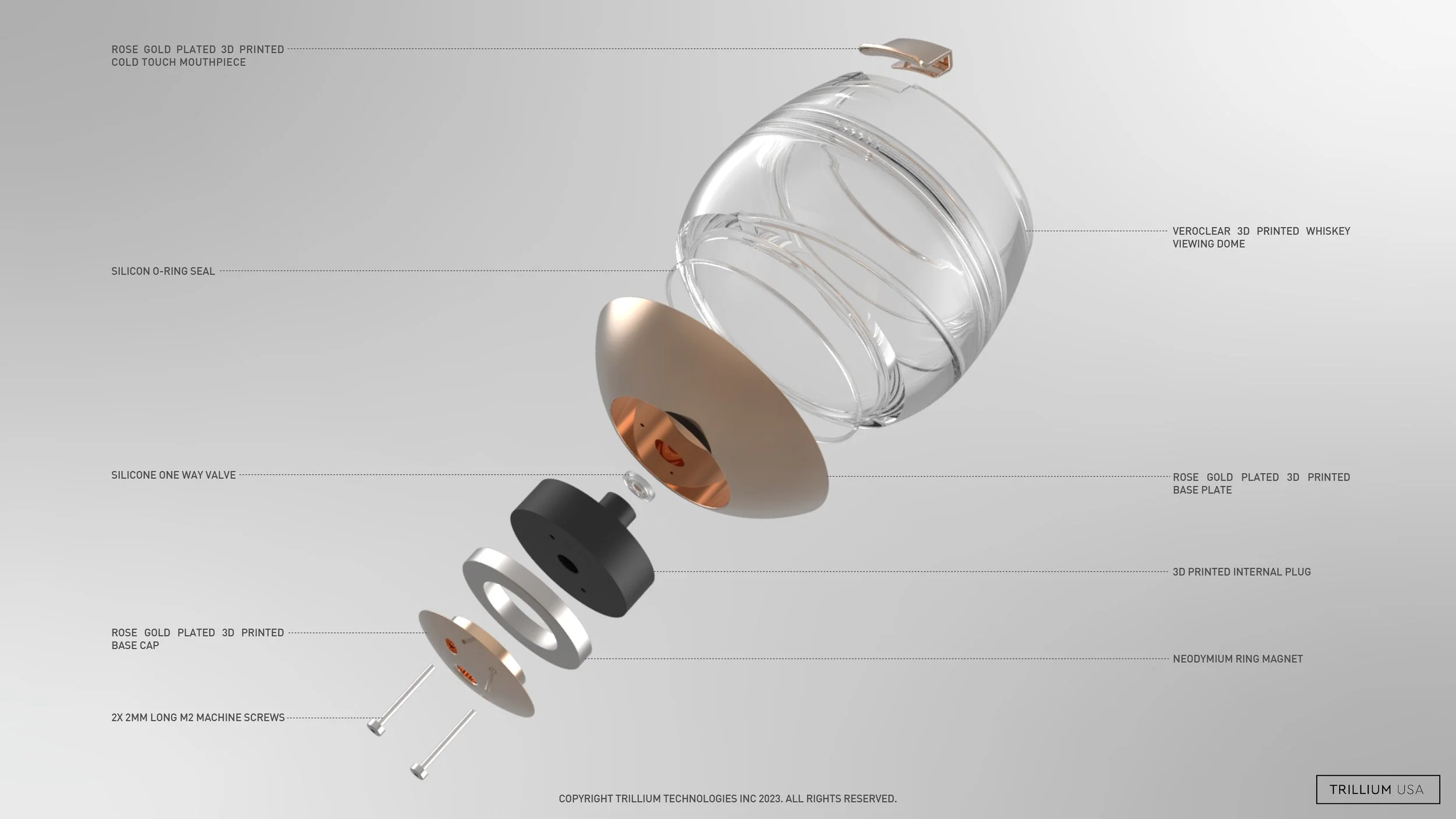

Our team went through several iterations of the space glass design. How do we fill the glass? How do we drink from it? How do we keep the whiskey from floating away? The challenge was to not only create a simple, practical, and attractive whiskey glass, but to make one that could be 3D printed in space as well.

The result is shown in the images below. The unique design of the glass is based around a helical channel embedded on the glass’ internal wall. This structure allows the drinker to draw the whiskey up as they slowly swirl the glass, just as you would a traditional whiskey glass.

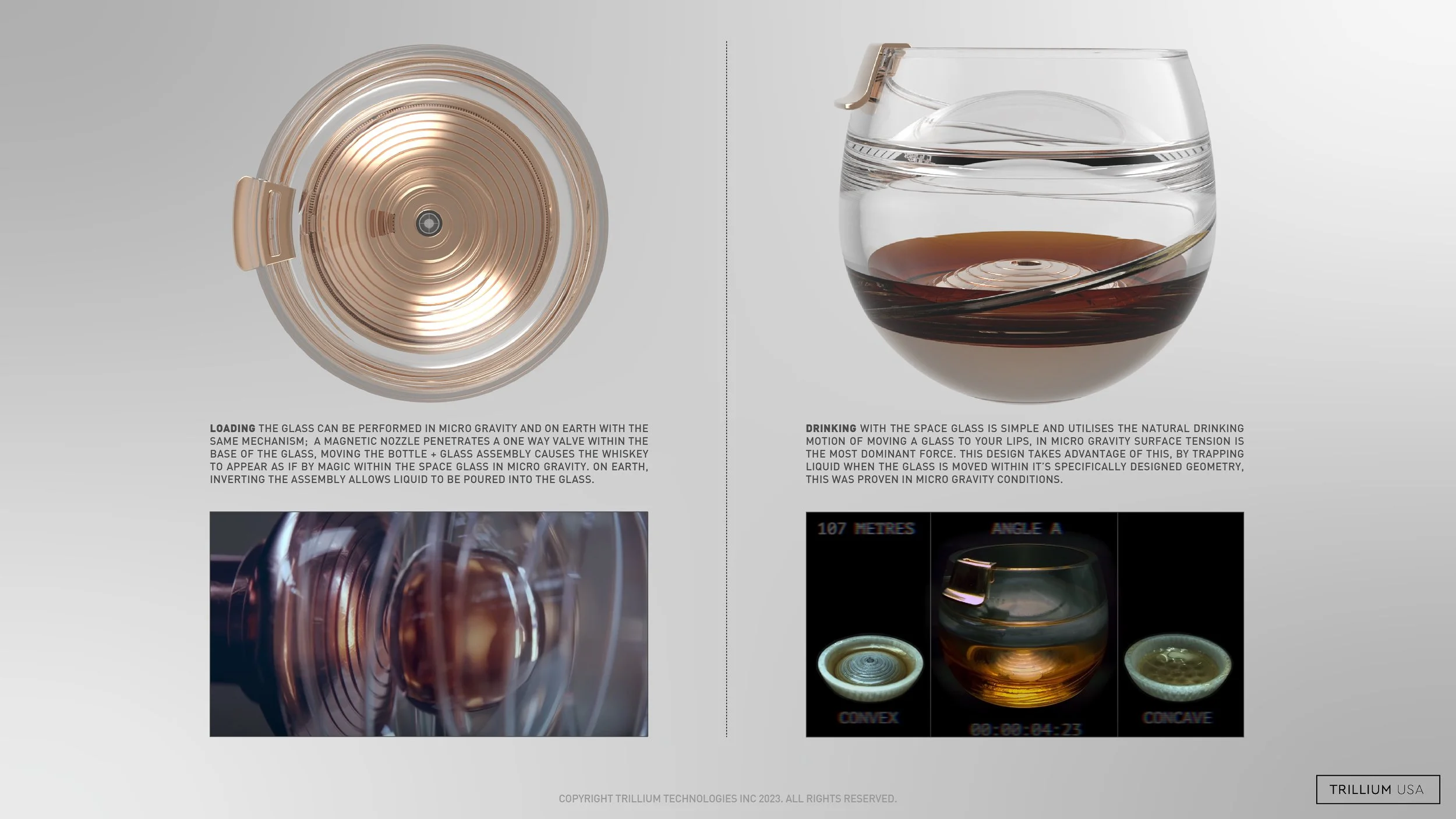

To keep the whiskey from floating away, we created a dome-shaped enclosure that would enable the whiskey to gently aerate as it moves around the glass. A special one-way valve and loading mechanism was designed so that the glass could be filled from the bottom. A simple solution for one of the most challenging environments.

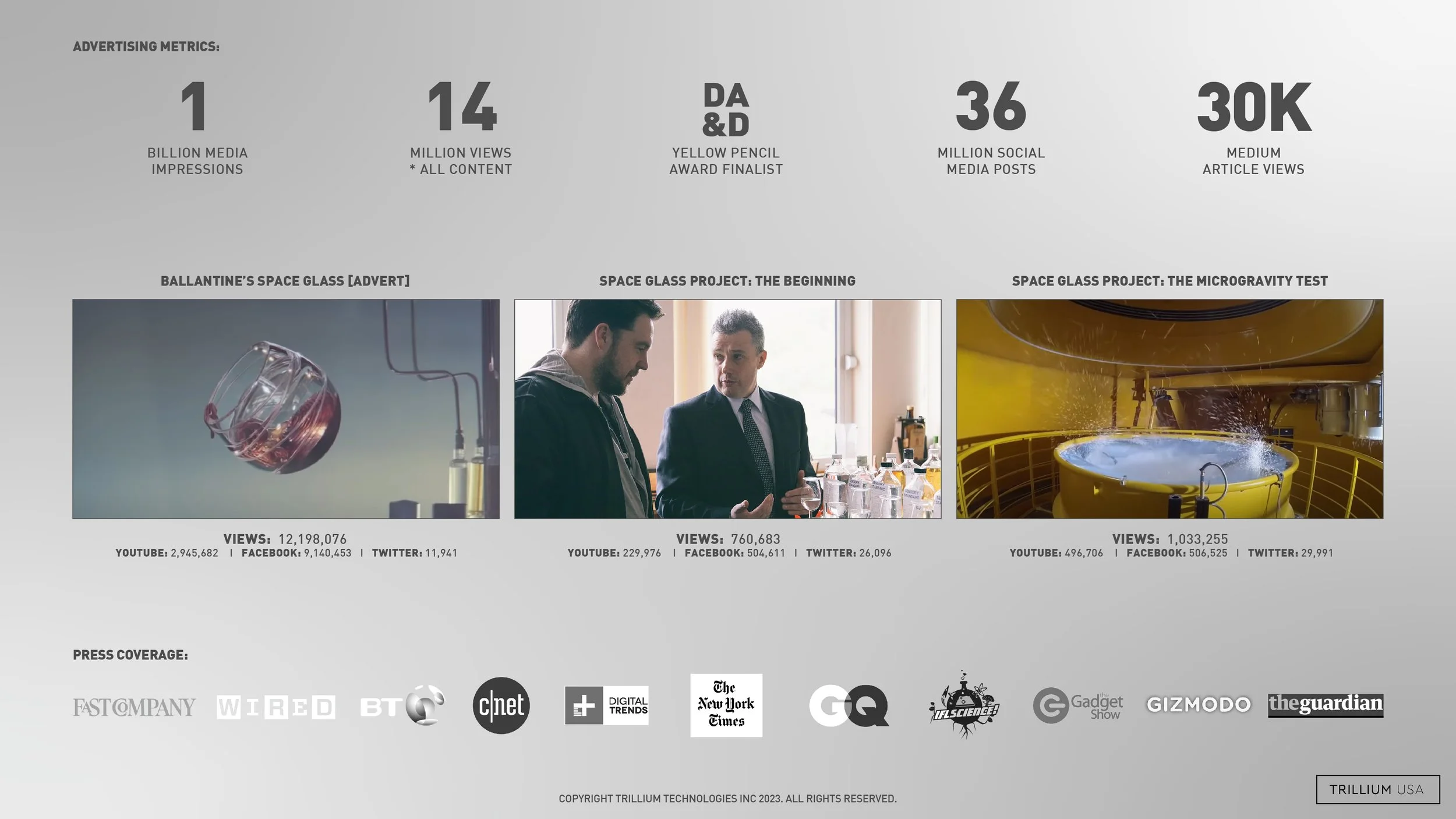

To test our design, our team traveled to Bremen, Germany to use Zarm’s 480-foot tall drop tower. The team filled the glass with whiskey and watched as it dropped down the vacuum-sealed shaft. The high-tech tower simulates microgravity, demonstrating for four seconds how the glass would perform in complete weightlessness.

The test was successful, and Ballantine’s launched Space Glass to a warm reception from the space, media, and makers community. More from Ballantine’s.